A Complete Guide to Flexible Printed Circuit Board is an essential read for anyone looking to learn more about this technology. The guide provides an overview of the different types of flexible PCBs, their applications and how they are manufactured. It also includes a section on design considerations and tips for optimizing performance.

Introduction to Flexible Printed Circuit Board

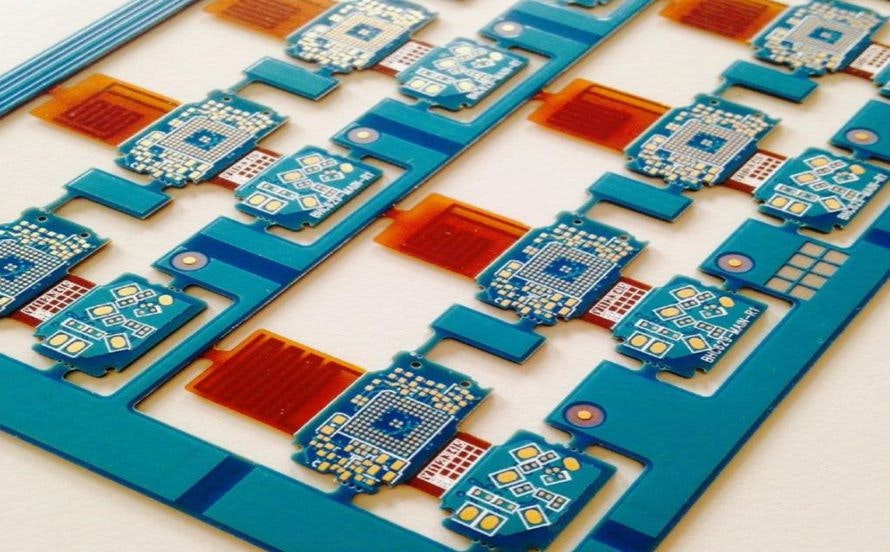

Flexible printed circuit board is a kind of printed circuit board which is made up of thin, flexible and insulating material. It is very easy to use and can be easily rolled up or folded. Flexible printed circuit board is very thin and light in weight as compared to other types of printed circuit boards.

The working of a flexible printed circuit board is very similar to that of a rigid printed circuit board. The only difference is that the former is made up of thin and flexible material which makes it easy to use.

Flexible printed circuit board has a number of advantages over other types of printed circuit boards. The most important advantage is that it is very easy to use. It can be easily rolled up or folded, which makes it very easy to carry around. Moreover, it is very thin and light in weight, which makes it very easy to handle.

Another advantage of flexible printed circuit board is that it is very tough and durable. It can withstand a lot of wear and tear and is not easily damaged.

Flexible printed circuit board is also very easy to manufacture. The process of manufacturing is very simple and does not require a lot of time or effort.

Flexible printed circuit board has a number of applications. It is widely used in the electronics industry for a variety of purposes. It is also used in the automotive industry for a variety of purposes.

Flexible printed circuit board is a very useful invention and has a number of advantages over other types of printed circuit boards. It is very easy to use and can be easily rolled up or folded. Moreover, it is very thin and light in weight, which makes it very easy to handle. It is also very tough and durable and can withstand a lot of wear and tear.

What is a Flexible Printed Circuit Board?

A flexible printed circuit board (FPCB) is a type of printed circuit board (PCB) that is made of a flexible material. They are used in a variety of electronics applications where flexibility and weight are important factors.

Flexible printed circuit boards are made of a thin, flexible material, such as polyimide, and have a conductive layer, such as copper, on one or both sides. They are used in a variety of applications, including cell phones, laptops, and digital cameras, where they replace traditional, rigid PCBs.

Flexible printed circuit boards are lighter and more durable than their rigid counterparts, and can be bent or folded to fit into smaller spaces. They are also more resistant to shock and vibration, making them ideal for use in portable electronic devices.

Drawbacks of flexible printed circuit boards include their higher cost and the fact that they are more difficult to repair than rigid PCBs.

Advantages of Flexible Printed Circuit Board

A flexible printed circuit board (FPCB) is a multilayer printed circuit board where the substrate is a flexible material. This allows the board to be bent, twisted, or rolled without damage.

There are many advantages to using an FPCB over a traditional rigid printed circuit board. First, they are much lighter and more portable, making them ideal for use in mobile devices. Second, they are much more resistant to vibration and shock, making them ideal for use in harsh environments. Third, they are much more flexible in terms of design, making them ideal for use in a wide variety of applications.

Fourth, FPCBs can be manufactured using a variety of different materials, including plastic, metal, and even glass. This gives designers a wide range of options when it comes to choosing the right material for their application. Fifth, FPCBs can be produced in a wide range of sizes and shapes, making them ideal for use in a variety of different applications.

Finally, FPCBs are typically much less expensive than their rigid counterparts. This is due to the fact that they can be manufactured using a variety of different methods, including roll-to-roll, screen printing, and direct write.

How to make a Flexible Printed Circuit Board?

A flexible printed circuit board (FPCB) is a type of printed circuit board (PCB) that is flexible in nature. They are used in a variety of electronic devices and have a wide range of applications.

FPCBs are made of a thin, flexible substrate that is coated with a conductive material. The substrate is typically made of polyimide, polyester, or polyethylene. The conductive material can be copper, gold, or silver.

The main advantage of FPCBs is that they are much more flexible than traditional PCBs. This makes them ideal for use in a variety of applications where space is limited or where the PCB needs to be able to bend or flex.

Some common applications for FPCBs include:

- Laptops

- Cell phones

- Wearable electronics

- Flexible displays

To make an FPCB, the first step is to create a master. This is typically done by photolithography. Once the master is created, it is used to create a negative or positive copy.

The next step is to coat the substrate with the conductive material. This can be done by sputtering, vapor deposition, or electroplating.

Once the conductive material is in place, the circuit can be printed on the substrate using a variety of methods, including screen printing, stencil printing, or direct write.

The last step is to cure the circuit. This can be done by heat, UV light, or electron beam.

FPCBs have a wide range of advantages over traditional PCBs. They are more flexible, which makes them ideal for use in a variety of applications. They are also thinner and lighter, which makes them easier to transport and install.

FPCBs are an essential component in a variety of electronic devices. If you are looking for a way to save space and weight in your next project, consider using an FPCB.

Tips for making a Flexible Printed Circuit Board

A flexible printed circuit board (FPCB) is a type of circuit board that is made of a flexible material. They are used in a variety of applications, including cell phones, laptops, and other electronic devices.

FPCBs are made by bonding a thin layer of copper onto a flexible substrate. The copper is then etched to create the desired circuit pattern. The substrate is typically made of polyimide, PEEK, or other flexible materials.

FPCBs offer several advantages over traditional rigid circuit boards. They are lighter, more durable, and less likely to crack or break. They can also be bent or rolled, making them ideal for applications where space is limited.

There are a few things to keep in mind when designing an FPCB. The circuit trace width and spacing must be carefully considered to ensure the traces can handle the required current. The board must also be designed to allow for expansion and contraction due to temperature changes.

Here are a few tips to help you design a successful FPCB:

-

Keep the traces as wide as possible to minimize resistance.

-

Use thicker copper for high-current traces.

-

Keep the trace spacing small to prevent crosstalk.

-

Use vias to connect different layers of the board.

-

Make sure the board can expand and contract without breaking the traces.

By following these tips, you can design a successful FPCB that will meet the needs of your application.

Conclusion

A Complete Guide to Flexible Printed Circuit Board offers a comprehensive overview of flexible PCB technology and manufacturing. It provides an in-depth explanation of the different types of flexible PCBs, their applications, and the manufacturing process. The guide also includes a discussion of the key factors to consider when selecting a flexible PCB manufacturer.