動機

アウトランダーPHEVに乗っているが、3年前に補機バッテリー上がりを経験した。その時は、ディーラーのモバイルバッテリーブースターで起動してもらい、様子を見ることになった。

その約7か月後に再び、補機バッテリー上がりとなり、補機バッテリーを交換することになった。その頃から補機バッテリーの電圧を取得することを考え始めた。

調べていくうちに、トラ技2022年8月号でRaspbery piとCAN通信を使ってODBⅡ経由で車の状態を取得できることを知り、方向が違うが興味を持ちやってみた。

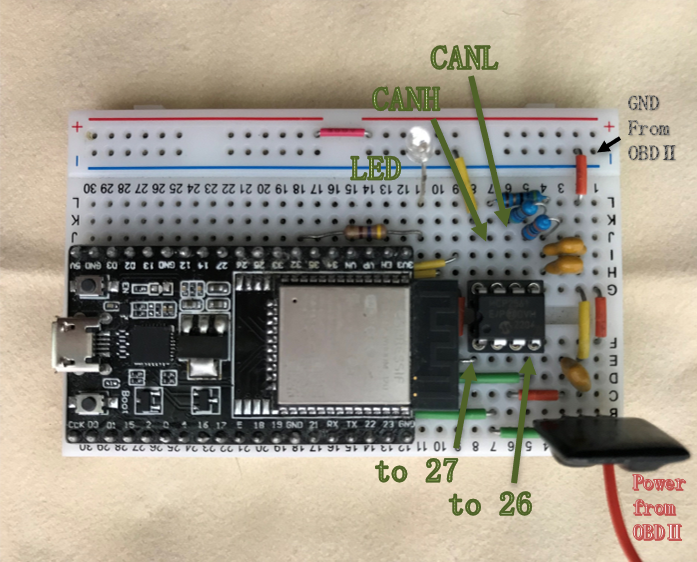

実際は、トラ技の記事だとCANコントローラーとCANトランシーバーが必要だったが、参考のページでは、ESP32とCANトランシーバーで出来ると書いてあったので、そちらで試してみることにした。

(何のことはない、ESP32がCANトラーバーの役目をしただけのことである。)

試したコード

#include <Arduino.h>

#include <CAN.h>

#include <OBD2.h>

#include <vector>

#define LED_PIN 32

std::vector<int> pids;

void setup()

{

pinMode(LED_PIN, OUTPUT);

digitalWrite(LED_PIN, HIGH);

Serial.begin(115200);

while (!Serial);

delay(500);

Serial.println(F("OBD2 Supported PIDs"));

CAN.setPins(26, 27);

// Attempting to connect to OBD2 CAN bus

while (true) {

Serial.print(F("Attempting to connect to OBD2 CAN bus ... "));

if (!OBD2.begin())

{

Serial.println(F("failed!"));

}

else

{

Serial.println(F("success"));

break;

}

delay(1000);

digitalWrite(LED_PIN, (uint8_t)(digitalRead(LED_PIN) == LOW ? HIGH : LOW));

}

digitalWrite(LED_PIN, HIGH);

// Get OBD-II Suport PIDs

// loop through PIDs 0 to 95, reading and printing the names of the supported PIDs

for (int pid = 0; pid < 96; pid++) {

if (OBD2.pidSupported(pid)) {

Serial.println(OBD2.pidName(pid));

pids.push_back(pid);

}

}

digitalWrite(LED_PIN, LOW);

}

void loop()

{

digitalWrite(LED_PIN, (uint8_t)(digitalRead(LED_PIN) == LOW ? HIGH : LOW));

// get the value of PID which get in the vector earlier

for (int pid : pids)

{

printPID(pid);

delay(1);

}

Serial.println();

delay(1000);

}

void printPID(int pid) {

// print PID name

Serial.print(OBD2.pidName(pid));

Serial.print(F(" = "));

if (OBD2.pidValueRaw(pid))

{

// read the raw PID value

unsigned long pidRawValue = OBD2.pidReadRaw(pid);

Serial.print(F("0x"));

Serial.print(pidRawValue, HEX);

}

else

{

// read the PID value

float pidValue = OBD2.pidRead(pid);

if (isnan(pidValue)) {

Serial.print("error");

} else {

// print value with units

Serial.print(pidValue);

Serial.print(F(" "));

Serial.print(OBD2.pidUnits(pid));

}

}

Serial.println();

}

Exapmleでは目的のPIDの値を出力するものと、サポートされているPIDを取得するものとなっていたので、以下のコードを付け足してサポートされているPIDをSetup内部で取得して、そのPIDの値を出力するように改良した。サポートPIDをSetupで取得するコードが以下の部分。

pidsはvectorで、グローバル変数で宣言している。

// loop through PIDs 0 to 95, reading and printing the names of the supported PIDs

for (int pid = 0; pid < 96; pid++) {

if (OBD2.pidSupported(pid)) {

Serial.println(OBD2.pidName(pid));

pids.push_back(pid);

}

}

取得した結果

OBD2 Supported PIDs

Attempting to connect to OBD2 CAN bus ... failed! // IG off. But OBD-II Power line alive.

Attempting to connect to OBD2 CAN bus ... failed!

Attempting to connect to OBD2 CAN bus ... failed!

Attempting to connect to OBD2 CAN bus ... failed!

Attempting to connect to OBD2 CAN bus ... failed!

Attempting to connect to OBD2 CAN bus ... failed!

Attempting to connect to OBD2 CAN bus ... failed!

Attempting to connect to OBD2 CAN bus ... success // After IG on

PIDs supported [01 - 20]

Monitor status since DTCs cleared

Fuel system status

Calculated engine load

Engine coolant temperature

Short term fuel trim - Bank 1

Long term fuel trim - Bank 1

Intake manifold absolute pressure

Engine RPM

Vehicle speed

Timing advance

Intake air temperature

MAF air flow rate

Throttle position

Oxygen sensors present (in 2 banks)

Oxygen Sensor 2 - Short term fuel trim

OBD standards this vehicle conforms to

Run time since engine start

PIDs supported [21 - 40]

Distance traveled with malfunction indicator lamp (MIL) on

Oxygen Sensor 1 - Fuel - Air Equivalence Ratio

Commanded EGR

Commanded evaporative purge

Fuel Tank Level Input

Warm-ups since codes cleared

Distance traveled since codes cleared

Absolute Barometric Pressure

PIDs supported [41 - 60]

Monitor status this drive cycle

Control module voltage

Absolute load value

Fuel - Air commanded equivalence ratio

Relative throttle position

Ambient air temperature

Absolute throttle position B

Commanded throttle actuator

Fuel Type

Relative accelerator pedal position

PIDs supported [01 - 20] = 0xBE3FA813 // start get (there was no blank line)

Monitor status since DTCs cleared = 0x76100

Fuel system status = 0x400

Calculated engine load = 0.00 %

Engine coolant temperature = 17.00 °C

Short term fuel trim - Bank 1 = 0.00 %

Long term fuel trim - Bank 1 = 0.00 %

Intake manifold absolute pressure = 104.00 kPa

Engine RPM = 0.00 rpm

Vehicle speed = 0.00 km/h

Timing advance = 61.00 ° before TDC

Intake air temperature = 17.00 °C

MAF air flow rate = 0.00 grams/sec

Throttle position = 15.69 %

Oxygen sensors present (in 2 banks) = 0x3

Oxygen Sensor 2 - Short term fuel trim = 0.00 %

OBD standards this vehicle conforms to = 0xA

Run time since engine start = 3.00 seconds

PIDs supported [21 - 40] = 0x9017A001

Distance traveled with malfunction indicator lamp (MIL) on = 0.00 km

Oxygen Sensor 1 - Fuel - Air Equivalence Ratio = 1.00 ratio

Commanded EGR = 0.00 %

Commanded evaporative purge = 0.00 %

Fuel Tank Level Input = 98.82 %

Warm-ups since codes cleared = 255.00 count

Distance traveled since codes cleared = 10637.00 km

Absolute Barometric Pressure = 101.00 kPa

PIDs supported [41 - 60] = 0xFE108040

Monitor status this drive cycle = 0x76161

Control module voltage = 14.50 V

Absolute load value = 0.00 %

Fuel - Air commanded equivalence ratio = 0.87 ratio

Relative throttle position = 8.24 %

Ambient air temperature = 17.00 °C

Absolute throttle position B = 16.47 %

Commanded throttle actuator = 8.24 %

Fuel Type = 0x0

Relative accelerator pedal position = 0.00 %

PIDs supported [01 - 20] = 0xBE3FA813 // second time

Monitor status since DTCs cleared = 0x76100

Fuel system status = 0x400

Calculated engine load = 0.00 %

Engine coolant temperature = 17.00 °C

Short term fuel trim - Bank 1 = 0.00 %

Long term fuel trim - Bank 1 = 0.00 %

Intake manifold absolute pressure = 104.00 kPa

Engine RPM = 0.00 rpm

Vehicle speed = 0.00 km/h

Timing advance = 61.00 ° before TDC

Intake air temperature = 17.00 °C

MAF air flow rate = 0.00 grams/sec

Throttle position = 15.69 %

Oxygen sensors present (in 2 banks) = 0x3

Oxygen Sensor 2 - Short term fuel trim = 0.00 %

OBD standards this vehicle conforms to = 0xA

Run time since engine start = 6.00 seconds

PIDs supported [21 - 40] = 0x9017A001

Distance traveled with malfunction indicator lamp (MIL) on = 0.00 km

Oxygen Sensor 1 - Fuel - Air Equivalence Ratio = 1.00 ratio

Commanded EGR = 0.00 %

Commanded evaporative purge = 0.00 %

Fuel Tank Level Input = 98.82 %

Warm-ups since codes cleared = 255.00 count

Distance traveled since codes cleared = 10637.00 km

Absolute Barometric Pressure = 101.00 kPa

PIDs supported [41 - 60] = 0xFE108040

Monitor status this drive cycle = 0x76161

Control module voltage = 14.50 V

Absolute load value = 0.00 %

Fuel - Air commanded equivalence ratio = 0.87 ratio

Relative throttle position = 8.24 %

Ambient air temperature = 17.00 °C

Absolute throttle position B = 16.47 %

Commanded throttle actuator = 8.24 %

Fuel Type = 0x0

Relative accelerator pedal position = 0.00 %

イグニッション-OFFにすると、データは来なくなる。

調べた事やった事

参考ページ

CANからODBⅡへ

Arduino用のCANライブラリは参考ページにあるこちらを使わせていただいた。

さらにページの下部にあるExamplesに下行があり、ODBⅡのライブラリが用意されていた。

For OBD-II examples, checkout the arduino-OBD2 library's examples.

集めた部品

ESP32 DevKitC V4 ESP-WROOM-32 ESP-32

(手元品:LDOは自前で強化品に変更してある。ねむいさんのぶろぐを参考に真似た)

AmazonからOBDⅡのコネクター(+電源、アース、CANH、CANLのみ)を入手した。

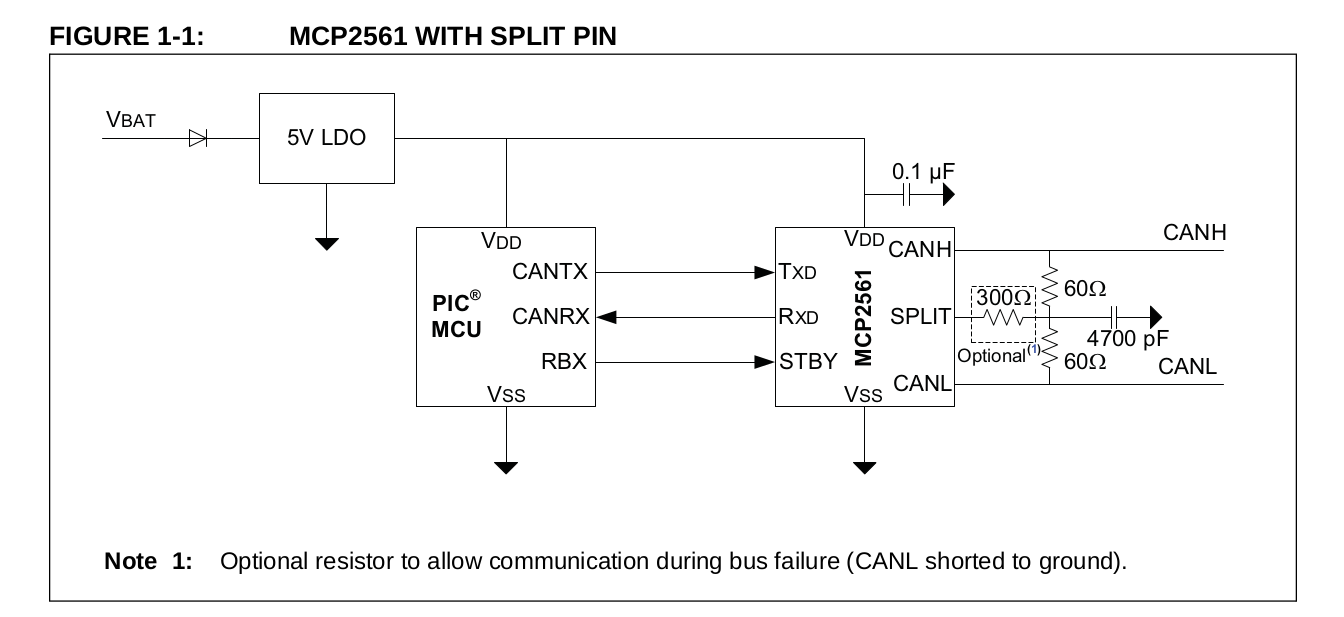

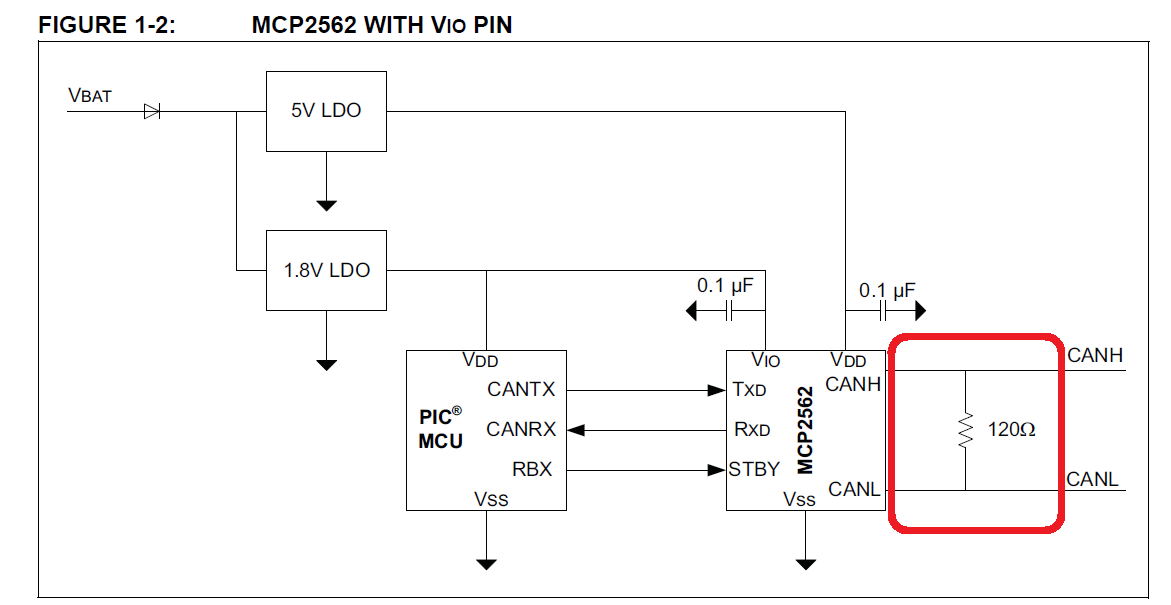

MCP2562は在庫切れだったので、MCP2561を購入

残り手元品

三端子DC/DCレギュレータ 5V( https://akizukidenshi.com/catalog/g/gM-11188/ )

レギュレータは、ESP32のONボードでも良かったと思うが、念のため。こちらを使った。結果OBDⅡの電源ラインは、イグニッション-OFFでも生きていることは分かった。

ブレッドボード、LED、抵抗、セラミックコンデンサ など

MCP2561

秋月電子よりMCP2561を入手(MCP2562は在庫切れだった)

MCP2562とは、CANH、CANLの物理インターフェース部の簡便さが違う。でも、1.8V LDOが別途必要なので、結果的にはMCP2561で良かったかも。

ブレッドボード外観

ESP32は、PCと接続して、シリアル出力を監視した。もちろんRaspbery piでもOK。(結局、トラ技と変わらないか???)