はじめに

- CPLEX CP Optimizerの資料で説明されている半導体ウエハー生産計画の最適化を再現してみた。

- https://www.slideshare.net/PhilippeLaborie/introduction-to-cp-optimizer-for-scheduling

- https://ibmdecisionoptimization.github.io/docplex-doc/cp/index.html

生産計画の仕様

- ロットは、ウエハーの数(n)、優先度(priority)、生産開始可能日(release_date)、納期(due_date)を持つ。

- ロット毎に、生産ステップのシーケンスが与えられる。

- ロットを構成するステップの間隔(lag)が長くなるとコストが発生する。

- 各ステップはファミリー(f)を持つ。

- ファミリーに対して、生産可能なマシンと生産時間(process_time)が与えられる。

- ファミリーが同じステップは同時に生産することができる。開始と終了は同じとなる。

- 生産するステップのファミリーを切替えるには一定の時間が掛かる。

- マシンはキャパシティ(capacity)を持つ。同時に生産できるウエハー数の上限値。

- 最小化する指標は、ステップ間隔コスト$V_1$と納期遅れコスト$V_2$の二つ。

\begin{align*}

V_1&=\sum_{\mathrm{Step}} \min(c,c\max(0,\mathrm{lag}-a)^2/(b-a)^2)\\

V_2&=\sum_{\mathrm{Lot}} p\max(0,\mathrm{EndOfLot}-\mathrm{DueDate})

\end{align*}

- ロット数: 1000

- ステップ数: 5000

- マシン数: 150

- 各ステップが生産可能なマシン数: 10

- 生産計画の期間は48時間で分単位

CP Optimizerによる実装

- プログラミング言語はOPL。CPLEX Optimization Studioで実行。

- 50行でExcellent Performanceが得られるとのこと。

- 変数名を長めに変更。

using CP;

tuple Lot { key int id; int n; float priority; int release_date; int due_date; }

tuple LotStep { key Lot lot; key int pos; int f; }

tuple Lag { Lot lot; int pos1; int pos2; int a; int b; float c; }

tuple Machine { key int id; int capacity; }

tuple MachineFamily { Machine machine; int f; int process_time; }

tuple MachineStep { Machine machine; LotStep lot_step; int process_time; }

tuple Setup { int f1; int f2; int duration; }

{Lot} Lots = ...;

{LotStep} LotSteps = ...;

{Lag} Lags = ...;

{Machine} Machines = ...;

{MachineFamily} MachineFamilies = ...;

{Setup} MachineSetups[machine in Machines] = ...;

{MachineStep} MachineSteps = {<machine_family.machine,lot_step,machine_family.process_time>

| lot_step in LotSteps, machine_family in MachineFamilies: machine_family.f==lot_step.f};

dvar interval d_lot[lot in Lots] in lot.release_date .. 48*60;

dvar interval d_lot_step[lot_step in LotSteps];

dvar interval d_machine_step[ms in MachineSteps] optional size ms.process_time;

dvar int d_lag[Lags];

stateFunction batch[machine in Machines] with MachineSetups[machine];

cumulFunction load [machine in Machines] =

sum(ms in MachineSteps: ms.machine==machine) pulse(d_machine_step[ms], ms.lot_step.lot.n);

minimize staticLex(

sum(lag in Lags) minl(lag.c, lag.c * maxl(0, d_lag[lag]-lag.a)^2 / (lag.b-lag.a)^2),

sum(lot in Lots) lot.priority * maxl(0, endOf(d_lot[lot]) - lot.due_date));

subject to {

forall(lot in Lots)

span(d_lot[lot], all(lot_step in LotSteps: lot_step.lot==lot) d_lot_step[lot_step]);

forall(lot_step in LotSteps) {

alternative(d_lot_step[lot_step], all(ms in MachineSteps: ms.lot_step==lot_step) d_machine_step[ms]);

if (lot_step.pos > 1)

endBeforeStart(d_lot_step[<lot_step.lot,lot_step.pos-1>],d_lot_step[lot_step]);

}

forall(ms in MachineSteps)

alwaysEqual(batch[ms.machine], d_machine_step[ms], ms.lot_step.f, true, true);

forall(machine in Machines)

load[machine] <= machine.capacity;

forall(lag in Lags)

endAtStart(d_lot_step[<lag.lot,lag.pos1>], d_lot_step[<lag.lot,lag.pos2>], d_lag[lag]);

}

サンプルデータの作成

乱数を使用してサンプルデータを作成。

alphaは生産開可能なマシンの比率。

from dataclasses import dataclass, field

import docplex.cp.model as cp

from docplex.cp.expression import CpoIntervalVar

import random

import pandas as pd

import numpy as np

@dataclass

class lot_type:

id: int

n: int

priority: float

release_date: int

due_date: int

step_list: list

@dataclass

class step_type:

id: int

family: int

a: float

b: float

c: float

start: int = field(init=False, default=0)

end: int = field(init=False, default=0)

machine_id: int = field(init=False, default=0)

@dataclass

class machine_type:

id: int

capacity: int

setup_list: list

proc_time: dict = field(init=False, default_factory=dict)

job_list: list = field(init=False, default_factory=list)

@dataclass

class setup_type:

family1: int

family2: int

duration: int

@dataclass

class job_type:

n: int

family: int

interval_var: CpoIntervalVar

start: int = field(init=False, default=0)

end: int = field(init=False, default=0)

random.seed(5)

n_lot, n_step, n_family, n_machine = 4, 5, 3, 4

lot_n = (5, 15)

capa = (20, 60)

proc_time = (20, 30)

takt, LT = 30, 100

a, b, c = 10, 20, 5

alpha = 0.5

duration = 20

lot_list = []

for l in range(n_lot):

n = random.randint(lot_n[0], lot_n[1])

p = random.randint(1, 10) / 10

step_list = [step_type(s, random.randint(0, n_family-1), a, b, c) for s in range(n_step)]

lot = lot_type(l, n, p, takt*l, takt*l+LT, step_list)

lot_list.append(lot)

machine_list = []

for m in range(n_machine):

setup_list = []

for j in range(n_family):

for k in range(n_family):

setup_list.append(setup_type(j, k, 0 if j == k else duration))

c = random.randint(capa[0], capa[1])

machine = machine_type(m, c, setup_list)

machine_list.append(machine)

for f in range(n_family):

cnt = 0

for m in range(n_machine):

if random.random() > alpha: continue

machine_list[m].proc_time[f] = random.randint(proc_time[0], proc_time[1])

cnt += 1

if cnt == 0:

m = random.randint(0, n_machine-1)

machine_list[m].proc_time[f] = random.randint(proc_time[0], proc_time[1])

CPLEX Optimization Studio用データの作成

path_file_name = 'sample.dat'

def mytuple(obj):

if type(obj) == lot_type:

return f'<{obj.id},{obj.n},{obj.priority},{obj.release_date},{obj.due_date}>'

if type(obj) == machine_type:

return f'<{obj.id},{obj.capacity}>'

with open(path_file_name, 'w') as o:

o.write('Lots = {\n')

for lot in lot_list:

o.write(f' {mytuple(lot)}\n')

o.write('};\n')

o.write('LotSteps = {\n')

for lot in lot_list:

for s, step in enumerate(lot.step_list):

o.write(f' <{mytuple(lot)},{s+1},{step.family}>\n')

o.write('};\n')

o.write('Lags = {\n')

for lot in lot_list:

for l in range(len(lot.step_list)-1):

step = step_list[s]

o.write(f' <{mytuple(lot)},{l+1},{l+2},{step.a},{step.b},{step.c}>\n')

o.write('};\n')

o.write('Machines = {\n')

for machine in machine_list:

o.write(f' {mytuple(machine)}\n')

o.write('};\n')

o.write('MachineFamilies = {\n')

for machine in machine_list:

for f, proc_time in machine.proc_time.items():

o.write(f' <{mytuple(machine)},{f},{proc_time}>\n')

o.write('};\n')

o.write('MachineSetups = #[\n')

for machine in machine_list:

o.write(f' <{machine.id}>:{{')

for setup in machine.setup_list:

o.write(f'<{setup.family1},{setup.family2},{setup.duration}>')

o.write('}\n')

o.write(']#;\n')

Python Libraryによる実装

サンプルデータの作成で使用したオブジェクトをそのまま流用。

モデルの作成と最適化、結果出力。

model = cp.CpoModel()

interval_name_to_step = {}

for lot in lot_list:

lot.interval_var = cp.interval_var(start=[lot.release_date,48*60], end=[lot.release_date,48*60], name=f'I{lot.id}')

for s, step in enumerate(lot.step_list):

step.interval_var = cp.interval_var(name=f'I{lot.id}_{s}')

interval_list = []

for machine in machine_list:

if step.family not in machine.proc_time: continue

name = f'I{lot.id}_{s}_{machine.id}'

interval_var = cp.interval_var(length=machine.proc_time[step.family], optional=True, name=name)

interval_list.append(interval_var)

machine.job_list.append(job_type(lot.n, step.family, interval_var))

interval_name_to_step[interval_var.name] = step

model.add(cp.alternative(step.interval_var, interval_list))

model.add(cp.span(lot.interval_var, [step.interval_var for step in lot.step_list]))

for s in range(len(lot.step_list)-1):

lot.step_list[s].int_var = cp.integer_var(min=0, max=48*60, name=f'A{lot.id}_{s}')

model.add(cp.end_at_start(lot.step_list[s].interval_var, lot.step_list[s+1].interval_var, lot.step_list[s].int_var))

for machine in machine_list:

tmat = cp.transition_matrix(n_family)

for setup in machine.setup_list:

tmat.set_value(setup.family1, setup.family2, setup.duration)

state = cp.state_function(tmat, name=f'S{machine.id}')

pulse_list = []

for job in machine.job_list:

model.add(cp.always_equal(state, job.interval_var, job.family, True, True))

pulse_list.append(cp.pulse(job.interval_var, job.n))

model.add(cp.sum(pulse_list) <= machine.capacity)

lag_list = []

for lot in lot_list:

for s in range(len(lot.step_list)-1):

step = lot.step_list[s]

lag_list.append(cp.min(step.c, step.c * cp.square(cp.max(0, step.int_var - step.a)) / (step.b - step.a)**2))

obj_lag = cp.sum(lag_list)

obj_lot = cp.sum([lot.priority * cp.max(0, cp.end_of(lot.interval_var) - lot.due_date) for lot in lot_list])

model.add(cp.minimize_static_lex([obj_lag, obj_lot]))

msol = model.solve(LogVerbosity='Terse', Workers=2, NoOverlapInferenceLevel='Medium', RandomSeed=1)

print(msol.get_search_status(), msol.get_objective_values())

最適化結果の出力

for machine in machine_list:

for job in machine.job_list:

x = msol.get_value(job.interval_var)

if(len(x) == 0):

job.n = 0

continue

job.start = x[0]

job.end = x[1]

step = interval_name_to_step[job.interval_var.name]

step.start = job.start

step.end = job.end

step.machine_id = machine.id

result = []

for lot in lot_list:

for step in lot.step_list:

result.append([lot.id, lot.n, lot.priority, lot.release_date, lot.due_date,

step.id, step.family, step.start, step.end, (step.end-step.start),

step.machine_id, machine_list[step.machine_id].capacity])

result = pd.DataFrame(result, columns=['lot', 'n', 'priority', 'release_date', 'due_date',

'step', 'family', 'start', 'end', 'size',

'machine', 'capacity'])

result.sort_values(['lot', 'start'], inplace=True, ignore_index=True)

result.to_csv('semi_cplex.csv', index=False)

実行結果

最適解が得られた。計算時間は0.1秒程度。

CP OptimizerでもPythonでも同一の結果となった。

| l | n | priority | release_date | due_date | pos | f | start | end | length | m | capacity |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 14 | 0.5 | 0 | 100 | 0 | 2 | 0 | 23 | 23 | 1 | 44 |

| 0 | 14 | 0.5 | 0 | 100 | 1 | 1 | 30 | 53 | 23 | 2 | 30 |

| 0 | 14 | 0.5 | 0 | 100 | 2 | 2 | 53 | 76 | 23 | 1 | 44 |

| 0 | 14 | 0.5 | 0 | 100 | 3 | 2 | 76 | 99 | 23 | 1 | 44 |

| 0 | 14 | 0.5 | 0 | 100 | 4 | 2 | 99 | 122 | 23 | 1 | 44 |

| 1 | 13 | 0.1 | 30 | 130 | 0 | 1 | 30 | 53 | 23 | 2 | 30 |

| 1 | 13 | 0.1 | 30 | 130 | 1 | 0 | 53 | 76 | 23 | 3 | 24 |

| 1 | 13 | 0.1 | 30 | 130 | 2 | 2 | 76 | 99 | 23 | 1 | 44 |

| 1 | 13 | 0.1 | 30 | 130 | 3 | 0 | 99 | 128 | 29 | 0 | 31 |

| 1 | 13 | 0.1 | 30 | 130 | 4 | 0 | 128 | 151 | 23 | 3 | 24 |

| 2 | 6 | 0.6 | 60 | 160 | 0 | 1 | 60 | 83 | 23 | 2 | 30 |

| 2 | 6 | 0.6 | 60 | 160 | 1 | 0 | 83 | 106 | 23 | 3 | 24 |

| 2 | 6 | 0.6 | 60 | 160 | 2 | 1 | 106 | 129 | 23 | 2 | 30 |

| 2 | 6 | 0.6 | 60 | 160 | 3 | 2 | 129 | 152 | 23 | 1 | 44 |

| 2 | 6 | 0.6 | 60 | 160 | 4 | 0 | 152 | 172 | 20 | 2 | 30 |

| 3 | 14 | 0.4 | 90 | 190 | 0 | 0 | 99 | 128 | 29 | 0 | 31 |

| 3 | 14 | 0.4 | 90 | 190 | 1 | 2 | 129 | 152 | 23 | 1 | 44 |

| 3 | 14 | 0.4 | 90 | 190 | 2 | 0 | 152 | 172 | 20 | 2 | 30 |

| 3 | 14 | 0.4 | 90 | 190 | 3 | 1 | 172 | 194 | 22 | 1 | 44 |

| 3 | 14 | 0.4 | 90 | 190 | 4 | 1 | 194 | 216 | 22 | 1 | 44 |

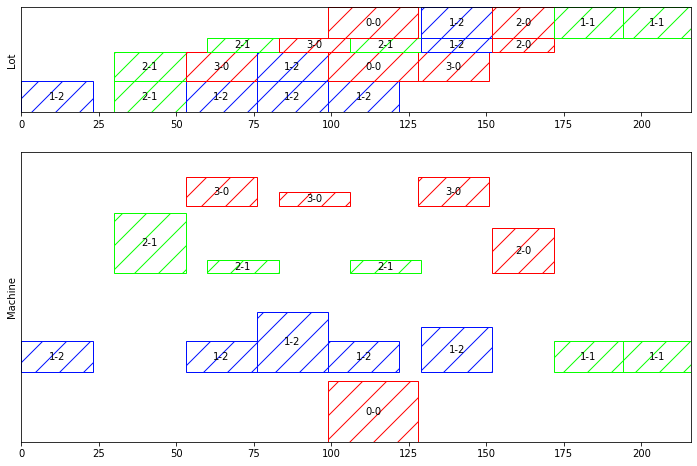

ガントチャートの出力

import matplotlib

import matplotlib.pyplot as plt

from matplotlib import gridspec

area_w = max([step.end for lot in lot_list for step in lot.step_list])

lot_h = np.array([lot.n for lot in lot_list])

area_lot_h = sum(lot_h)

machine_h = np.array([machine.capacity for machine in machine_list])

area_machine_h = sum(machine_h)

for machine in machine_list:

machine.job_list.sort(key=lambda job: job.start)

i = 0

j = 1

while i < len(machine.job_list) and j < len(machine.job_list):

job_i = machine.job_list[i]

job_j = machine.job_list[j]

if job_i.n == 0 or job_i.start < job_j.start:

i = j

j = j+1

continue

if job_j.n == 0:

j = j+1

continue

job_i.n += job_j.n

job_j.n = 0

j = j+1

lot_y = np.cumsum(lot_h) - lot_h

def lot_generator():

for lot in lot_list:

for step in lot.step_list:

yield (step.start, lot_y[lot.id], (step.end-step.start), lot.n, step.family, f'{step.machine_id}-{step.family}')

machine_y = np.cumsum(machine_h) - machine_h

def machine_generator():

for machine in machine_list:

for job in machine.job_list:

if job.n == 0: continue

yield (job.start, machine_y[machine.id], (job.end-job.start), job.n, job.family, f'{machine.id}-{job.family}')

my_rect = matplotlib.patches.Rectangle

cmap = plt.cm.get_cmap('hsv', n_family+1)

fig = plt.figure(figsize=(12, 8))

spec = gridspec.GridSpec(ncols=1, nrows=2, height_ratios=[area_lot_h, area_machine_h])

def draw_box(ax, box_generator):

for (x,y,w,h,f,lab) in box_generator():

rectangle = my_rect((x, y), w, h, fill=False, color=cmap(f), hatch='/')

ax.add_patch(rectangle)

rx, ry = rectangle.get_xy()

cx = rx + rectangle.get_width()/2

cy = ry + rectangle.get_height()/2

ax.annotate(lab, (cx, cy), ha='center', va='center')

ax = fig.add_subplot(spec[0], yticks=[], ylabel='Lot')

ax.set_xlim(0, area_w)

ax.set_ylim(0, area_lot_h)

draw_box(ax, lot_generator)

ax = fig.add_subplot(spec[1], yticks=[], ylabel='Machine')

ax.set_xlim(0, area_w)

ax.set_ylim(0, area_machine_h)

draw_box(ax, machine_generator)

plt.show()

ボックスの色はファミリーを表している。中のラベルはマシン番号とファミリー番号。

ファミリーの切り替えロスを避けるために、同じファミリーをなるべく連続して生産している。

同じファミリーであれば、マシンのキャパシティの範囲で、まとめ生産が可能。

おわりに

- 少し複雑な問題でも手軽に最適解が得られることは驚異的。

- Interval変数とOptional属性を使用すると生産計画モデルを簡単に表現することができる。

- ロット数1000でも解が得られるかどうかは未検証。Community Editionでは変数が多すぎる。